Our recent projects

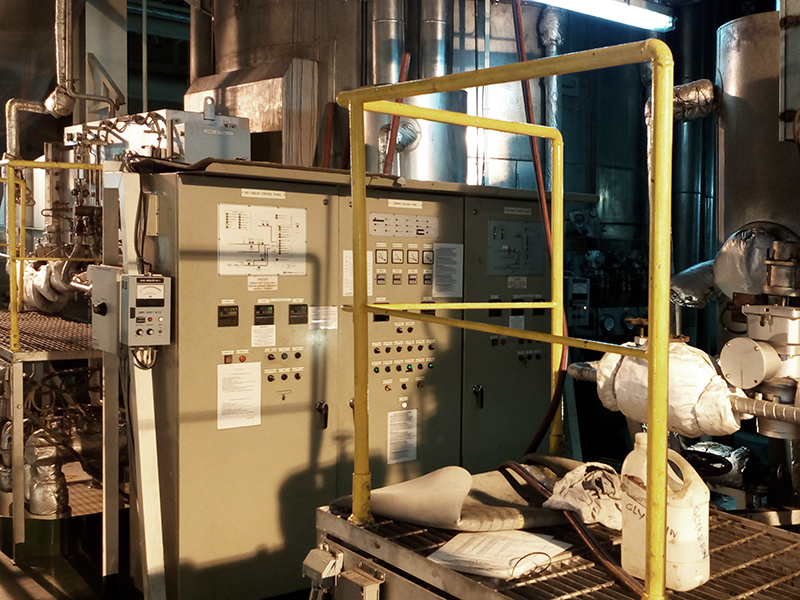

Control system upgrade for full auto operation (on tanker vessels)

Customer reported problem with auto operation of boiler plant and was asking for our assistance with this matter.

After inspection it was found that originally design of system is not made on proper way in order to follow auto operation principles. After collecting all necessary documentation and software’s from vessel, we proceed with necessary engineering.

Finally, we visit vessel one more time in order to perform service and make system fully operational. Control logic was changed from in order to follow the full auto operation principle:

• Both boilers selected in auto mode. • All controllers in auto mode (steam pressure controller, fuel flow controller and air flow controller).

• Master-slave operation.

• IG operation mode.

• Proper combustion control for HFO and MGO. After successful installation and confirmation of proper operation from customer we did this kind of upgrade for all sister vessels in their fleet.

Control system upgrade for burners which are made for continuous running on HFO and cold start on DO (on tanker vessels)

Customer reported problem with running of burner on MGO (problems with smoke during operation). After inspection it was found that originally design of system is not made in order to satisfy running of system on MGO. After collecting all necessary documentation and software’s from vessel, we proceed with necessary engineering. Finally, we visit vessel one more time in order to perform service and make system fully operational. Combustion control logic was changed in order to compensate the difference in viscosity between selected fuels and to ensure proper combustion. After successful installation and confirmation of proper operation from costumer we did this kind of upgrade for all sister vessels in their fleet.

Replacement of pneumatic positioners, controllers and actuators

Some of actuators are controlled by pneumatic positioners and controllers. In many cases due to control air contamination with oil and water, life span of equipment is extremely reduced. Also, many Korean build vessels are equipped with poor quality equipment. With replacement of this equipment with electronic positioners, controllers and actuators we match operation principles and achieve reliable operation. Those kinds of replacements were implemented on many vessels after inspections and recommendations from our side.

Upgrade of electropneumatic control actuators

In many cases electropneumatic positioners on various control valves are obsolete, so it is not easy to find replacement in case of failure. With an upgrade of those equipment with standardized products we match operation principles and achieved reliable operation.

Those kinds of replacements were implemented on many vessels after inspections and recommendations from our side.

Replacement of spring loaded control valves (valves used mostly for pressure control)

In many cases, spring loaded control valves are not very accurate and that kind of control is causing problems in operation of the system. With replacement of this equipment with electronic positioners, controllers and actuators we match operation principles and achieved reliable operation. Those kinds of replacements were implemented on many vessels after inspections and recommendations from our side.

Upgrade of locally controlled valves to remote control from ECR (pressure and temperature control valves in purifier room, steam dumping valves)

Some controllers are installed locally on actuators and placed all around engine room. In some cases, it is very difficult for operators to follow all processes at the same time. With an upgrade of those equipment with remote electronic controllers placed in ECR we match operation principles and achieve reliable operation.

Those kinds of replacements were implemented on many vessels after inspections and recommendations from our side.

• NJOKO-SERVIS d.o.o is a company founded in 2016, by service engineers with many years of field service experience.

• We are specialized in engineering and field service of marine boilers (steam and TFO), burners and inert gas systems.

What We Do?

- Efficient and fast field service and commissioning for boilers, burners and inert gas systems of all major brands.

- Complete steam plant evaluation and optimization.

- Combustion adjustments and optimization.